Where Engineering Matters More Than Branding

“We make top-level automotive performance accessible, offering high-quality components at fair prices so more enthusiasts can enjoy track days and real driving performance. We promote transparency in global sourcing, recognizing the role of non-European manufacturers in today’s automotive materials and components.”

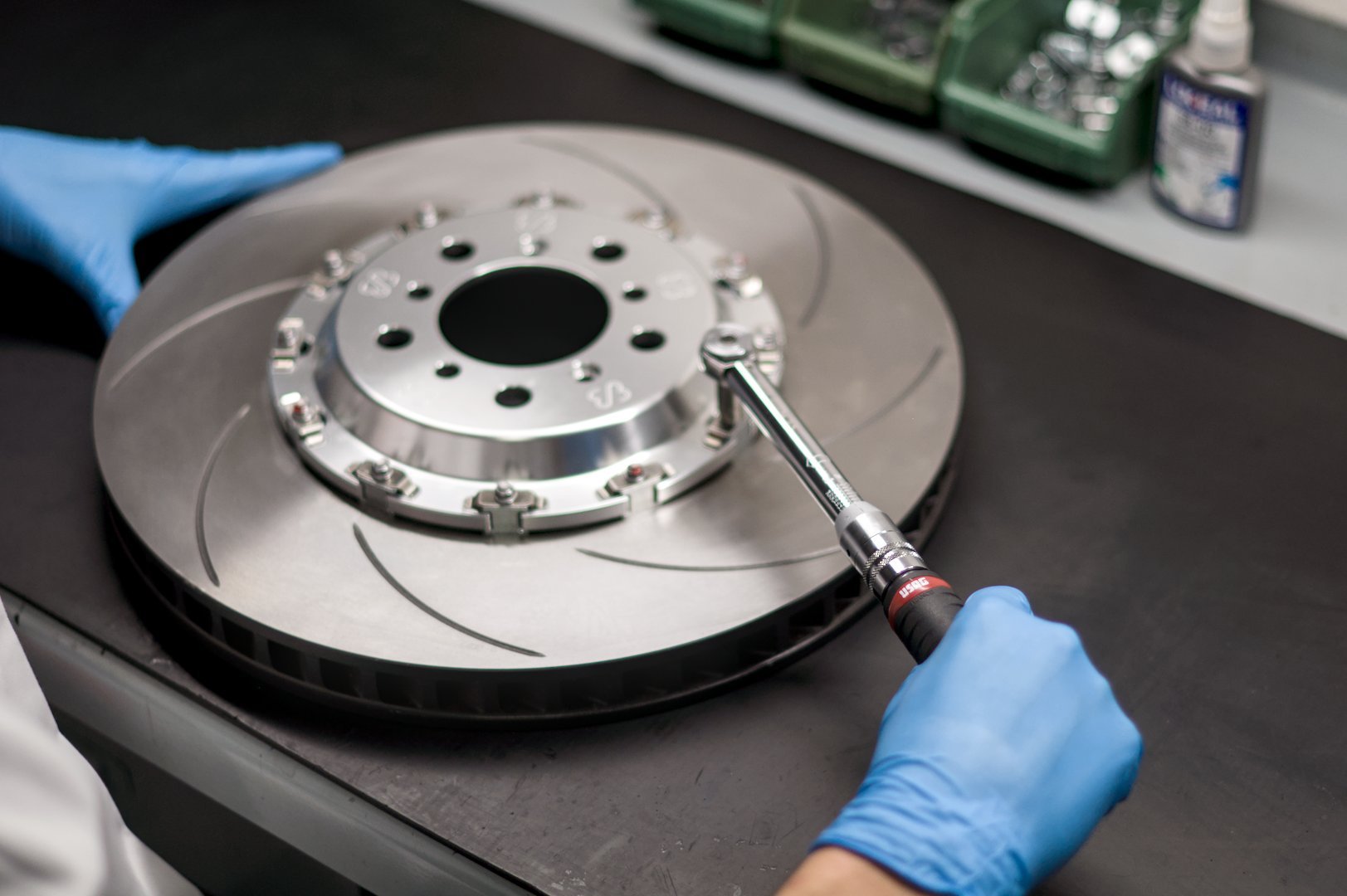

Our brake discs in detail

When you're pushing lap times on track days, time attack events, or endurance racing, your braking system needs to deliver consistent stopping power session after session. World4Track designs and manufactures floating brake discs that solve the thermal management challenges serious drivers face. Our two-piece rotors decouple the friction ring from the aluminium bell using precision bobbin hardware, allowing controlled radial expansion under extreme heat without warping or judder.

Every disc we produce starts with in-house CAD engineering, moves through thermal validation testing above 600°C, and proves itself on our own track cars before it ships to customers. We machine high-carbon cast iron friction rings with approximately 4% carbon content roughly 0.5% higher than competitor rotors, paired with vane counts ranging from 36 to 72 depending on application for maximum centrifugal air pumping and heat dissipation. Our 6061-T6 anodized aluminium hats reduce unsprung weight while high-strength cadmium-plated steel drive pins handle the shear loads. We validate fitment to strict tolerances: lateral runout ≤0.05mm, disc thickness variation ≤0.01mm across 8 sectors, and bell-to-ring concentricity ≤0.03mm at the PCD. Whether you're building a track car, upgrading a street car, or preparing for wheel-to-wheel competition, our floating rotors deliver predictable pedal feel, reduced rotating mass, and lap-after-lap repeatability. If it doesn't survive our thermal cycles and track testing protocol, it doesn't leave our facility, that's the engineering standard behind every World4Track brake disc.

Why choose World4Track?

World4Track is not a reseller. We are an engineering-driven brand.

Our components start with in-house research and development. We source raw materials, design and refine our products internally using CNC machining and precision measurement equipment, and validate every solution through real track use. Design, tolerances and performance targets are defined by us not by a third-party catalogue.

Once a design is proven, production is outsourced to trusted manufacturing partners. This allows us to deliver high-quality, technically controlled components at a sustainable cost, without compromising specifications or consistency. Where proven solutions already exist, we collaborate directly with selected overseas manufacturers and use them only after direct testing and validation. We do not reinvent parts unless it improves performance or reliability.

Every product we sell is either engineered by us or technically approved by us, installed on our own vehicles and tested under demanding conditions. Fitment, performance and durability are known — not assumed.

And if an issue ever arises, you deal with one point of contact. We handle the technical side, the manufacturing dialogue and the resolution so you can focus on driving.

Performance is not about hype, but measurable results. That’s why we carefully select and rigorously test components from trusted manufacturers around the world, focusing on engineering quality, materials and production standards rather than brand names. Every product is evaluated for real-world reliability and consistency under demanding conditions. We offer high-quality upgrades that deliver a noticeable and repeatable difference, both on the track and in everyday driving. Our approach prioritises transparent sourcing, proven durability and genuine performance gains you can feel every time you push the limits, ensuring confidence not only in peak performance but also in long-term use.